32/34, Jintan Udhyognagar, Behind Gas godown, Surendranagar – 363 002, Gujarat, INDIA.

ABOUT US

WE TAKE PRIDE IN TERRIFIC PRECISION

WHO WE ARE?

PINNACLE Engineering Enterprise is a Leading Manufacturer of High Precision Surface Grinding machines. Having its roots in the year 1986, today the company has an Experience of over 4 decades. 1800+ Installations of High Quality Surface Grinding machines stand testimony of the strong Foothold in the Machine tool Industry.

We, PINNACLE have earned a paramount reputation in the Machine Tools Industry by offering genuine results to our customers through our High Precision surface grinders.

Pinnacle’s strong motivated team of engineers, responsive marketing, solid support from manufacturers, prompt service has resulted in customer delight and propelled PINNACLE to a position of leadership today. The key to Success comes from high quality performance, coupled with excellent sales & service support.

STRENGTH

CONSTANT UPGRADATION

PINNACLE Engineering Enterprise has a team of Engineers lead by experienced Engineer leaders constantly guiding them to work on improving the design which is focused on Improving the quality, Ergonomic design, easy operating & least maintenance of the machine.

The company has changed its basic design completely 2 times from 1986 till 2016 thus providing better quality machines every time by constantly decreasing maintenance cost each time & is currently supplying the 3rd Generation PINNACLE - make High Precision Surface grinding machines to its valued customers.

The latest Surface grinding machines are manufactured by the latest European concept of surface grinding machines design i.e. Column moving design. The company has constantly upgraded & improved its design to help customers reach the PINNACLE quality offered by its machines.

NATURALLY SEASONED CASTINGS.

PINNACLE Engineering Enterprise believes in keeping it’s foundation strong. The company maintains a strong policy & system of converting only the naturally seasoned castings into the finished products. The company maintains the stock of enough machine castings for natural seasoning for at least next 1 year.

The process of natural seasoning is very well-known & most common practice practiced by the global machine tools manufacturers. The process helps in relieving stress-strain of the machine castings naturally thus not causing any deformation in the long run which maintains the accuracy of the machine and improves the life of the machine.

In case of customised CNC Profile, Creep feed & Spline grinding machines, the company offers artificial seasoning.

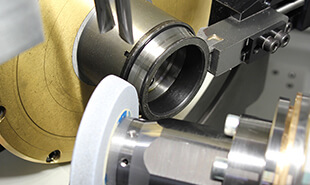

IN HOUSE MANUFACTURING

The quality of PINNACLE - make High precision surface grinding machines very much depends on its one of the most promising factor i.e. very well established In-house manufacturing facilities & processes.

In-house manufacturing not only helps the company to maintain the quality of all the spare parts & the machine but also helps in maintaining the exact inventory required for its machines. It provides flexibility to the company to change its design immediately for constant upgradation with quick customization in the processes involved.

The company manufactures its own Precision spindles-cartridges, Hydraulic Power packs & Precision Lead screw-Nut. It also has its own Pattern shop and Machine shop.

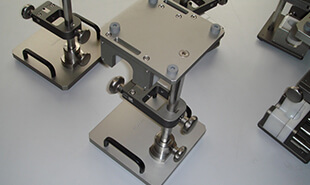

INTERCHAGABILITY OF PARTS.

The company is well equipped with Precision Jigs-Fixtures & a perfectly well defined process for the manufacturing of each and every spare part of the machines. The spare parts of the machines are manufactured on CNC Turning centers, CNC machining centers, Slide way Grinding machines & High Precision Cylindrical grinding machines with simultaneous intense use of Jigs & Fixtures.

The use of the latest technology & precision machines helps the company maintain its spare parts in very close tolerances thus helping its customers the ease of interchanging the parts as and when required.

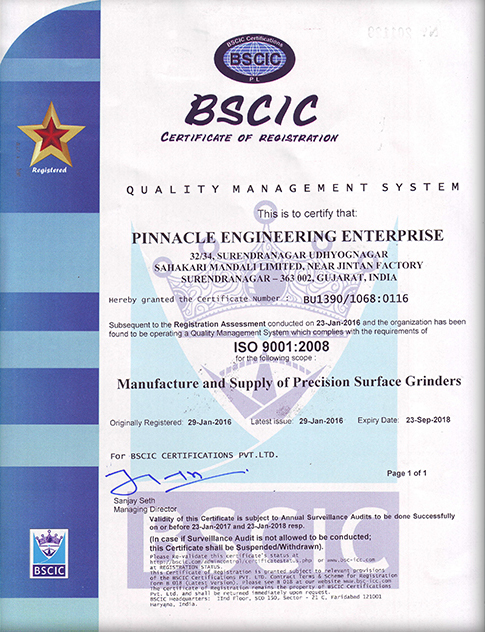

CERTIFICATION

Quality has always been our forte and to achieve this, we have established strict quality policies, which are followed within the organizational hierarchy. Each of our manufactured High Precision Surface Grinders and Rotary Grinders, there undergoes a series of strict Internal Inspection procedures that minimize every possibility of quality degradation.

The finest quality of components are used only after quality testing from our Technical team of qualified & experienced quality Engineers to completely ensure that there will always be a flow of excellent machinery from our manufacturing facility.

Our Quality Assurance team makes sure that each and every manufactured Surface Grinders are strictly checked out for Quality on these basic parameters:

-

High Accuracy

-

Ergonomics

-

Ease of operation

-

Aesthetics

-

Design Compliance

-

Interchangeability

INDUSTRIES

SERVED

PINNACLE offers the widest range of High Precision surface grinding machines to help resolve any challenge faced by our clients in the process of Surface Grinding. Have a glimpse on to the wide range of Industries that has overcome its Surface Grinding challenges from our High Precision Surface Grinding machines.

Automobile

Aerospace

Energy

Die Moulds

Tooling

Machine Manufacturers

Pumps & Valves

Medical

Diamond & Jewellery

Bearings

Job Work

Tool Room

Jigs & Fixtures

Forging Industries

Wood Industries

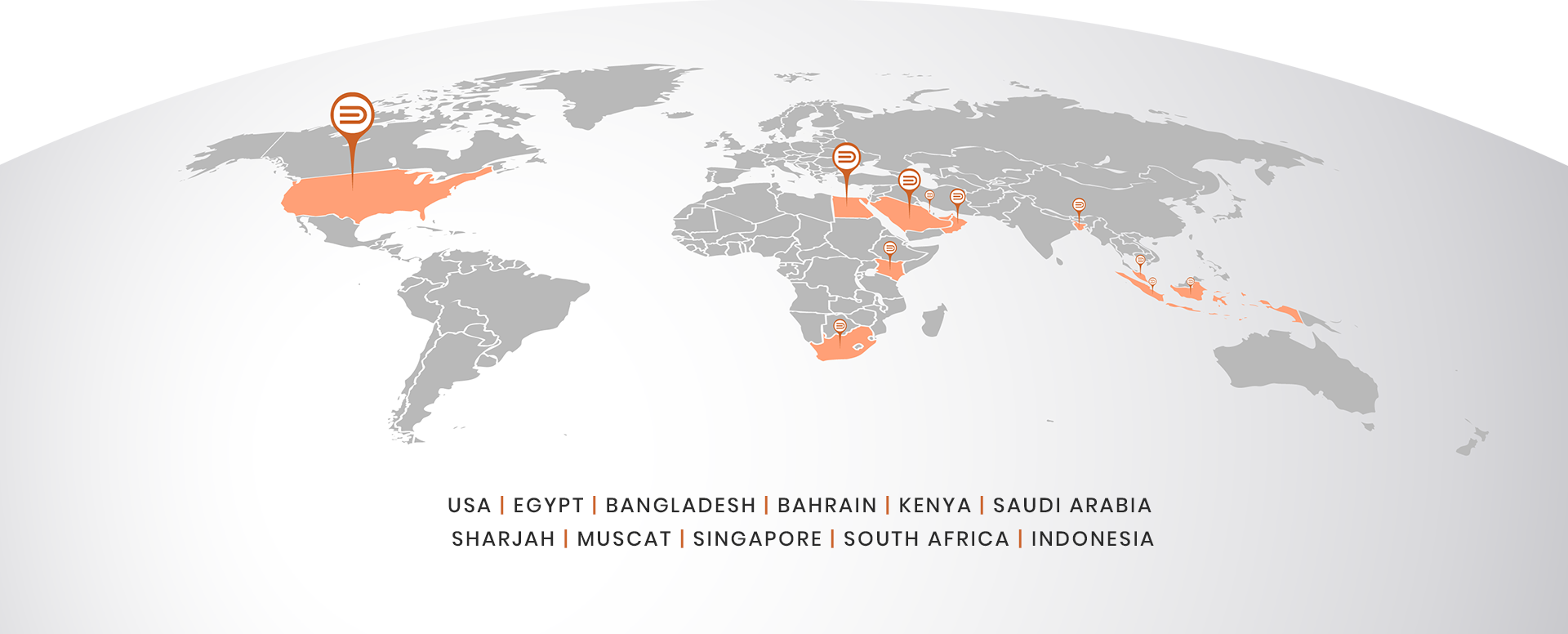

EXPORT NETWORK

Pinnacle’s wings are spread Worldwide and the High Quality Surface Grinding machines do not

only serve the Indian giants but the machines have also been exported to various parts of the Globe such as

USA, Egypt, Bangladesh, Bahrain, Kenya, Saudi Arabia, Sharjah, Muskat, Singapore, South Africa, Indonesia.

WHAT OUR

LOGO REPRESENTS

Spell the Identity

Logo itself depicts P for Parmar as it is a family run business & Pinnacle. The E in Logo also stands for Engineering Enterprise.

C for Customers

Logo is the mirror image of C for Customers. It depicts that the reason of Pinnacle’success is its Customers & Pinnacle has thus slowly emerged as the magnet in the market to attract customers.

Micron Symbol

Logo is a part of micron symbol.

4 Triangles

4 triangles in the Tag line depicts that we are constantly increasing & upgrading our machines by Precision, Technology & Customization.