32/34, Jintan Udhyognagar, Behind Gas godown, Surendranagar – 363 002, Gujarat, INDIA.

What are the 5 Key Benefits

of Surface Grinding Machine?

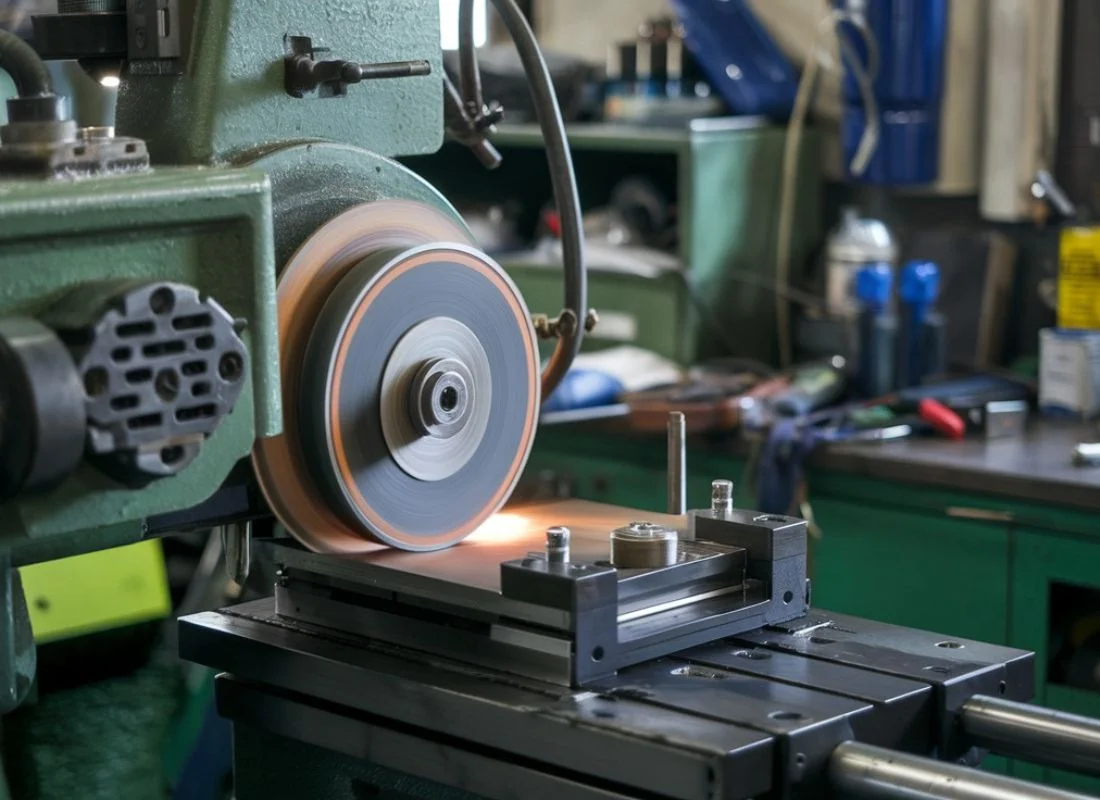

Surface grinding machines are important gear in manufacturing, providing accuracy, versatility, and a smooth end to substances. These machines use a spinning abrasive wheel to smooth flat surfaces, turning in a level of precision that's essential throughout industries from cars to aerospace.

Whether used for sprucing, completing, or smoothing materials, floor grinding machines streamline procedures and deliver extraordinary consequences. In this newsletter, we'll discover the pinnacle five key Benefits of Surface Grinding Machines and why they're integral in production.

Amazing Precision And Accuracy

One of the main benefits of surface grinding machine is its exquisite precision and accuracy. While machining parts, attaining an excessive diploma of accuracy is crucial for components that want to be healthy collectively with precision. Floor grinding machines make sure that substances are processed to genuine dimensions, with tolerances that could attain as tight as zero.001 millimeters. This level of precision is difficult to acquire with different machining procedures, which may lack the identical stage of control and consistency.

For manufacturers, this precision ensures that each element is uniform, which is mainly important in industries where actual measurements are vital for protection and characteristics, including aerospace, car, and medical gadgets. The accuracy of a floor grinding machine provides a basis for growing merchandise that meets strict specifications and standards.

Easy Surface End

Every other principal gain of surface grinding machines is their capacity to create a really easy surface end. These machines take away small, undesirable substances from the floor, generating a satisfactory, polished appearance that's tough to obtain with other machining methods. Floor grinding machines are frequently utilized in industries wherein aesthetics matter or wherein a low-friction surface is essential.

The easy floor end additionally has sensible Surface Grinding Machine Benefits: it reduces the hazard of corrosion, minimizes floor flaws, and can improve the functionality of additives. for example, elements in mechanical structures with an easy end often enjoy less wear and tear, extending their life span and improving the product's typical performance. For any manufacturer, this potential to provide a wonderful end is a considerable benefit of using a floor grinding device.

Excessive Efficiency And Pace

Surface grinding machines provide high performance and pace, which is critical in today's speedy-paced manufacturing environments. Surface grinding machines work quicker than many conventional machining procedures, as they are able to manage large volumes of substances without sacrificing high quality. This high-speed processing may be critical when meeting tight cut-off dates or coping with large-scale initiatives.

The efficiency of floor grinding machines translates into time and financial savings, which can drastically lessen manufacturing costs and add to Surface Grinding Machine Benefits. With the advantage of automation options in modern-day grinding machines, operators can set parameters for regular, repeatable grinding, similarly boosting performance. By reducing production time whilst preserving fines, floor grinding machines make notable contributions to the productivity of any production operation.

Versatility Across Substances

One often left-out benefit of floor grinding machines is their versatility. Those machines are able to grind a wide range of substances, including metals, alloys, and non-metallic substances, such as ceramics, plastics, and composites. This versatility permits producers to apply one device for various components and materials, making the floor grinding device a value-powerful and adaptable solution.

Unique industries can also have precise material necessities, and floor grinding machines can handle the diversity. For instance, aerospace components may additionally require grinding on lightweight alloys, even as automotive components regularly need hardened metal. floor grinding machines adapt to those demands, handing over regular results across materials and ensuring that producers can meet enterprise-precise standards while not having multiple sorts of systems.

Recommended for you: Various Types of Surface Grinding Machines

More Advantageous Cloth Durability And Strength

The surface grinding system contributes to the durability and strength of the substances being laboured on. By way of smoothing and levelling the floor, surface grinding machines dispose of imperfections that could weaken substances. This adds to the Benefits of the Surface Grinding Machine. Removing floor flaws is no longer the most effective way to improve the arrival; however, it additionally strengthens the integrity of the substances. This is particularly beneficial in industries wherein additives are subjected to excessive stress, as even minor imperfections can result in premature wear or failure.

For instance, components used in heavy machinery or car programs need to resist regular stress and friction. Surface grinding creates a wonderful end that provides strength and durability, enhancing the cloth's resilience and lengthening its provider life. This prolonged durability is a crucial advantage of floor grinding machines because it minimizes replacement fees and guarantees that parts can face up to demanding conditions.

Conclusion

Floor grinding machines deliver several blessings to production approaches, from wonderful precision and smooth finishes to elevated performance and material versatility. Their capacity to method extensive substances with excessive accuracy makes them useful throughout industries that demand the best standards, which include automotive, aerospace, and scientific device manufacturing. Moreover, the enhanced sturdiness and power of substances processed with floor grinding machines upload some other layer of price to this device.

For any enterprise that relies on precise, durable, and high-performance components, the Benefits of a Surface Grinding Machine can not be overstated. Their blessings ensure green, value-effective production that meets specific specifications and high standards. Through investing in surface grinding technology, manufacturers gain a powerful tool that supports regular quality, lengthy-lasting materials, and streamlined techniques, making it an indispensable part of modern-day manufacturing.