32/34, Jintan Udhyognagar, Behind Gas godown, Surendranagar – 363 002, Gujarat, INDIA.

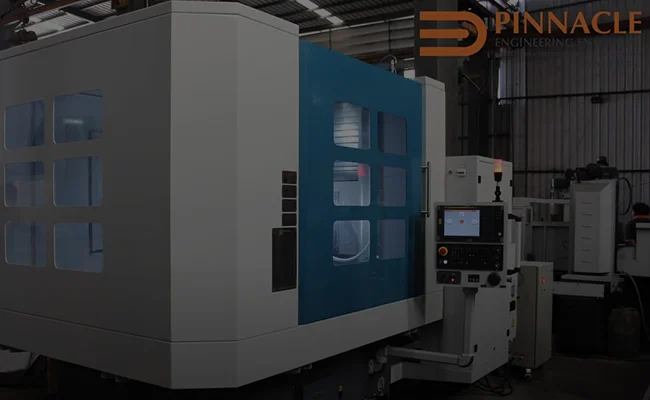

SALIENT FEATURES

-

Naturally seasoned Castings equivalent to Meehanite grade.

-

Robust & Sturdy design for precise grinding results over long period of time.

-

OPTIMUM ribbing for more stability with Maximum vibration Damping capacity.

-

Ergonomic design for simple & easy operating.

-

Precision Guide ways with anti-friction Turcite B-lined material in all Three Axes.

-

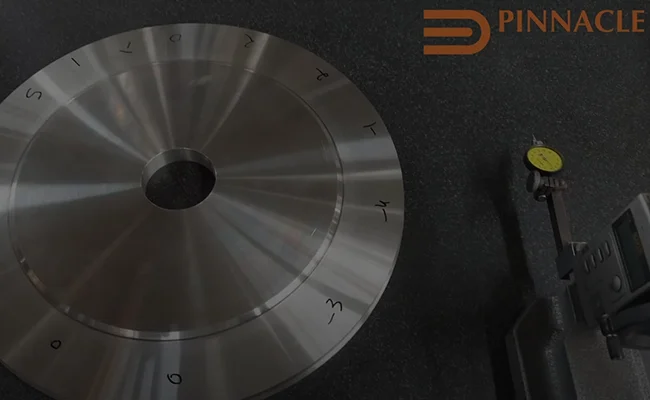

Infinitely variable Incremental Auto Cross Feed to have desired Surface finish & accuracy in Grinding and desired Dressing.

-

Set Separate Auto Cross Feed for Rough, Finish & Fine Grinding cycles.

-

Natural Air Cooled Lubrication unit provided separately for easy servicing.

-

No overhanging in guide ways as per European Column moving design concept.

-

Interlocks on Spindle Rotation/Magnetic Chuck.

-

Machine is equipped with Fully Developed Macro Cycles making it the most convenient for Machine operation.

-

Unique facility to undertake Vertical depth of cut from inside, outside & both sides of the table.

-

Each & every important messages/alarms during the Auto Grinding cycle regarding important factors like Coolant & Lubrication is clearly mentioned in the MOP.

-

Counter Weight Balancing in Y-Axis i.e., Vertical Axis for 1500 mm Table Diameter.

KEY FEATURES

-

Fully Enclosed Grinding area.

-

Developed Auto Grinding cycles with Auto dressing & Auto compensation.

-

Perfect Squareness of all B,Y & Z Axes.

-

Developed cycle for taking easy Grinding & Dressing offsets.

-

Electronic Hand Wheel with Least Count of 0.001 mm in Y & Z Axes.