32/34, Jintan Udhyognagar, Behind Gas godown, Surendranagar – 363 002, Gujarat, INDIA.

SALIENT FEATURES

-

Moving Column Design.

-

Naturally Seasoned / Stress Relieved castings.

-

OPTIMUM ribbing for more stability with Maximum vibration Damping capacity.

-

Infinitely variable Incremental Auto Cross Feed.

-

Robust & Sturdy design for precise grinding results over long period of time.

-

Natural Air Cooled Lubrication unit provided separately for easy servicing.

-

Criss Cross grinding provision.

-

Max. Table Speed of 25 m/min.

-

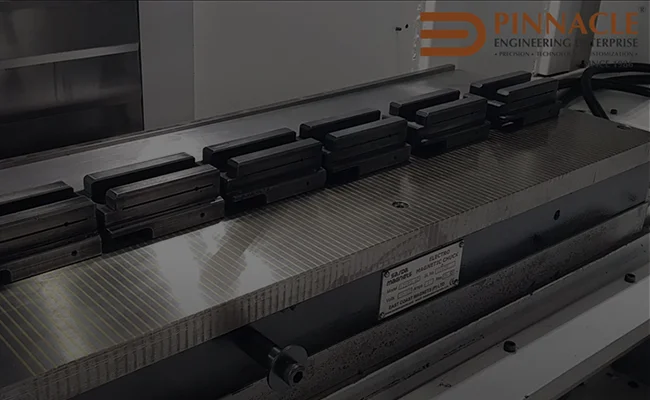

No overhanging in Guide ways.

-

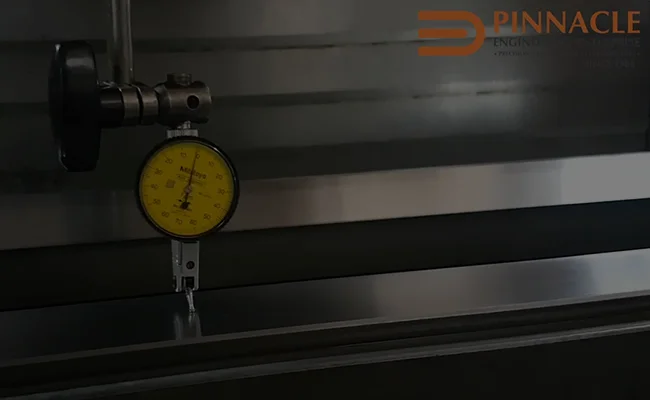

Perfect Squareness of all X,Y & Z Axes.

-

Programmable Auto Cross feed at each table stroke.

-

Auto Dressing with Auto Compensation.

-

3 Point Chisel Type Diamond Dresser.

-

Centralized Auto Lubrication system in all Axes & Screws.

CNC 3 Axes System's Standard Functions

-

Controlled X, Y & Z Axes

-

Least command Increment of 0.001 mm

-

Acceleration/Deceleration

-

Feed rate over drive 120%

-

Rapid Positioning

-

Linear Interpolation

-

Circular Interpolation

-

Manual Reference Point Return

-

M. P. G.

-

Dwell

-

Dry Run

-

Single Block