32/34, Jintan Udhyognagar, Behind Gas godown, Surendranagar – 363 002, Gujarat, INDIA.

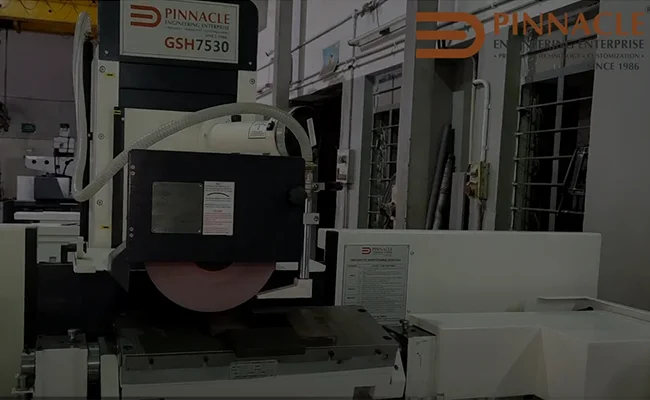

SALIENT FEATURES

-

Naturally seasoned Castings equivalent to Meehanite grade.

-

Robust & Sturdy design for precise grinding results over long period of time.

-

OPTIMUM ribbing for more stability with Maximum vibration Damping capacity.

-

Ergonomic design for simple & easy operating.

-

Precision Ground Guide ways with anti-friction Turcite B-lined material in all 3 Axes.

-

Infinitely variable Incremental Auto Cross Feed to have desired Surface finish & accuracy in Grinding and desired Dressing.

-

Water Baffles to protect Cross Guide ways from coolant & grinding dust.

-

Natural Air Cooled Hydraulic Power pack provided separately for easy servicing.

-

No overhanging in guide ways as per European Column moving design concept.

-

Interlocks on Spindle Rotation/Magnetic Chuck.

-

Criss Cross (Continuous) Grinding provision for higher material removal in less Cycle time.

KEY FEATURES

-

Max. Table Speed of 30 m/min.

-

Imported Super Precision bearings packed with Grease for life.

-

Interlocks on Spindle Rotation/Magnetic Chuck.

-

Perfect Squareness of all X,Y & Z Axes.

-

Centralized Auto Lubrication system in all Axes & Screws.