32/34, Jintan Udhyognagar, Behind Gas godown, Surendranagar – 363 002, Gujarat, INDIA.

Importance of Surface

Grinding in Precision

Engineering

Introduction:

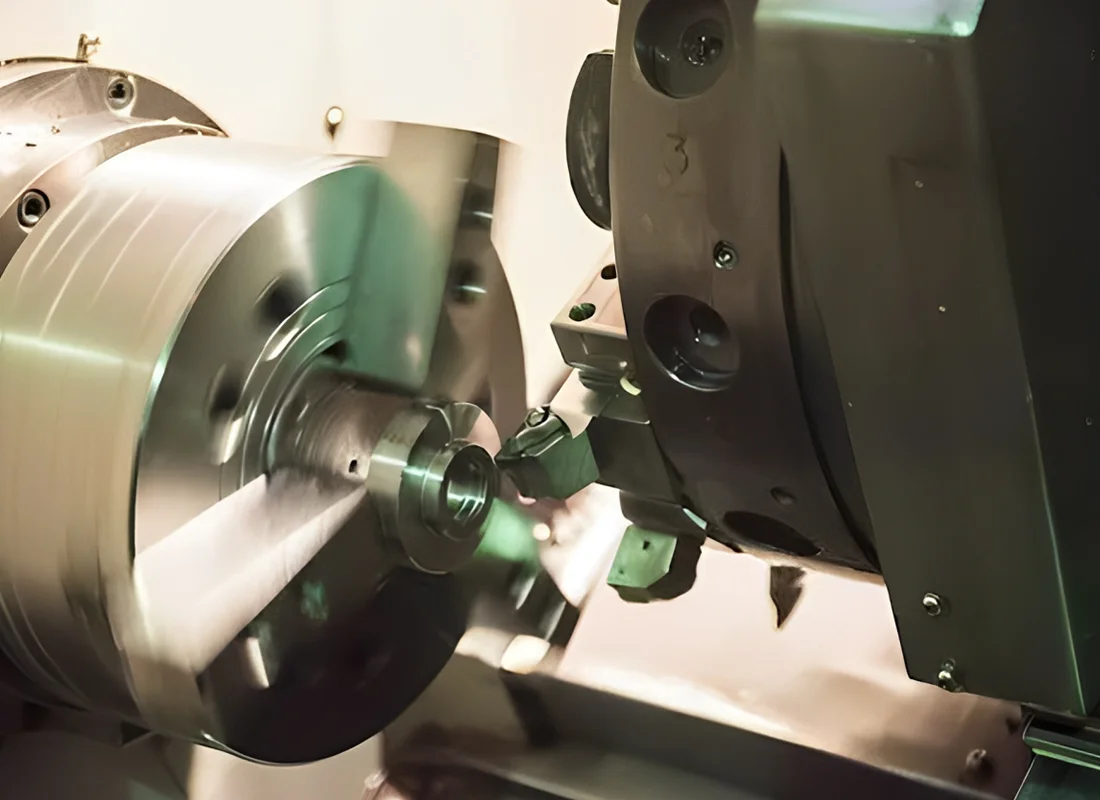

In the high-stakes realm of precision engineering, where a single micron can mean the difference between success and failure, surface grinding quietly holds the reins. This unassuming process—often overshadowed by flashier technologies like 3D printing—is the unsung hero ensuring that critical components function flawlessly.

From the turbine blades powering intercontinental flights to the life-saving implants in a patient’s body, surface grinding is the invisible hand shaping reliability. Here is why the importance of surface grinding method remains irreplaceable even when innovation is constant.

The Key Components of Surface Grinding

At its core, surface grinding is about subtraction. A spinning abrasive wheel, armed with grit harder than the workpiece itself, shaves off layers thinner than a human hair. The goal isn’t just to make things smooth—it’s to engineer surfaces so precise they defy the limits of conventional machining.

Consider a turbine disk in a jet engine. During operation, it spins at 15,000 RPM, enduring forces that could warp lesser materials. Before installation, that disk undergoes surface grinding to achieve a flatness within 0.0002 inches. Any deviation? The imbalance could trigger vibrations capable of shaking bolts loose mid-flight.

Key Elements Driving This Precision:

- Abrasive Science: Wheels made of aluminum oxide handle everyday steel, while diamond grit tackles ceramics or carbides.

- Thermal Control: Coolant isn’t optional. Without it, friction-induced heat can anneal hardened steel, softening it like butter.

- Fixturing Mastery: Magnetic chucks anchor parts during grinding, but non-ferrous materials like titanium demand vacuum plates or custom clamps.

The Importance of Surface Grinding in Achieving Precision

The Importance of Surface Grinding lies in its ability to achieve high precision and smooth finishes. It ensures accurate dimensions, improves component quality, and enhances durability, making it essential for industries demanding precise parts and superior performance.

1. Survival Under Stress

In aerospace, a turbine blade’s lifespan hinges on its surface finish. Microscopic ridges left by rough grinding create stress points where cracks nucleate. Precision surface grinding machine eliminates these flaws, extending component life by decades. The same principle applies to orthopaedic implants: a rough titanium hip joint abrades bone, while a mirror-smooth surface fuses seamlessly.

2. The Cost of “Almost Right”

An automotive supplier once ground a batch of transmission gears to “near-spec” tolerances. Within months, drivers reported whining noises—a result of gears meshing unevenly. The recall cost eclipsed $5 million. Surface grinding’s precision isn’t about luxury; it’s about avoiding disasters that ripple through supply chains.

3. Enabling Miniaturization

Modern electronics rely on components like silicon wafers, where surface flatness impacts circuit performance. A wafer uneven by 0.001 inches could render a microchip useless. Precision surface grinder delivers the sub-micron flatness needed for today’s nano-scale tech.

Key Industries Where Surface Grinding Excels

- Medical Miracles: Surgical scalpels ground to 0.1-micron sharpness slice tissue cleanly, reducing trauma and healing time.

- Energy Frontiers: Wind turbine shafts ground to perfection rotate smoothly for decades, minimizing maintenance in offshore rigs.

- Automotive Evolution: Electric vehicle battery plates require flawless flatness to prevent short circuits. Surface grinding delivers.

Key Factors to Select Surface Grinding Machine Manufacturers

- Ask for Certifications: ISO 9001 is table stakes. For aerospace, demand AS9100.

- Demand Samples: If they won’t grind a test piece for free, walk away.

- Check Their Coolant Game: Smelly, recycled coolant breeds bacteria that pit surfaces. Top shops use filtered systems.

A telling example: When a luxury watchmaker switched to manual grinding for gear components, customer returns for “sticky” movements dropped by 70%. The reason? Eliminating burrs invisible to the naked eye.

Manual vs. CNC: The Eternal Debate

- Manual Grinding: Favored for bespoke parts. A veteran grinder in Switzerland once crafted a custom camshaft for a vintage Ferrari using nothing but a manual machine and a lifetime of intuition.

- CNC Grinding: CNC Grinding: The choice for volume. A single CNC cell can grind 500 identical fuel injectors daily, each within 0.0001-inch tolerances.

Choosing a Grinding Partner: Red Flags and Green Lights

- AI-Powered Optimization: Sensors now monitor wheel wear in real-time, auto-adjusting feeds to maintain consistency.

- Eco-Conscious Grinding: Biodegradable coolants and energy-recuperative systems are slashing the process’s carbon footprint.

- Hybrid Materials: New composites and ceramics demand grinding wheels embedded with synthetic diamonds—pushing abrasive tech into uncharted territory.

Conclusion

Surface grinding isn’t just a step in manufacturing; it’s the final gatekeeper of quality. In a world where engineers routinely push materials to their limits, this process ensures that components don’t just survive—they thrive. From the depths of oceanic drilling rigs to the vacuum of space, the importance of surface grinding is visible everywhere, unseen but indispensable.