32/34, Jintan Udhyognagar, Behind Gas godown, Surendranagar – 363 002, Gujarat, INDIA.

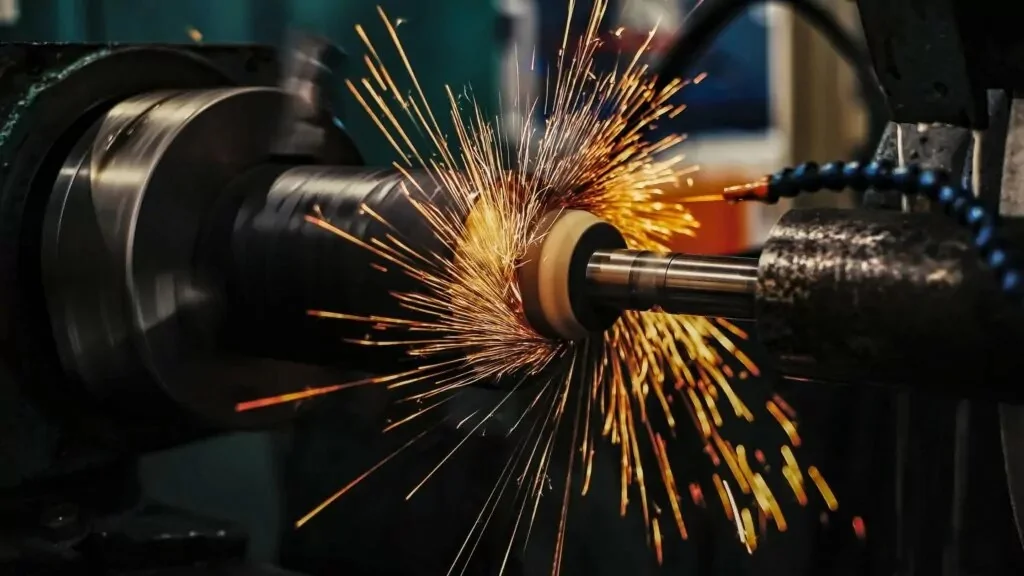

What are the Key Features of

Automatic Grinding Machine?

Introduction:

Indeed, in today’s fast-growing industrial world, the use of automated systems continues to be widely accepted within manufacturing systems. From the many changes sweeping over the industry, the automatic grinding machine is likely to have a profound impact on it.

So, to be aware of the possibilities of reaching the goals of precision, efficiency, and scalability for the industries of India it is significant to be mindful of the main parameters of an automatic grinding machine. Understanding the key features of Automatic Grinding Machines is highly pertinent in such Indian industries that are keen on precision, efficiency, and scalability.

Key Features of Automatic Grinding Machine

Automatic Grinding Machines are used in different industries for surface grinding. These machines have some quality features as follows:

Precision and Accuracy

The most important of the key features of an automatic grinding machine is the trueness and faithfulness of the grinding operation. It has managed to integrate more components, such as sensors and control systems, to produce consistently high-quality grinds. If you are using metal, glass, or even ceramics, the use of automatic grinding machines is efficient since it reduces the risk of distortion by repeating the same results time and again.

High efficiency and Productivity

The power-driven grinding machines are mainly suited for large-volume work to give optimal results. Their automation feature makes them run for most of the time hence low downtime. These machines are of great gain to the manufacturers in India, especially those manufacturing that experience an increasing demand and need for affordable price production lines to embrace high volume production time and time-tight deadlines.

Versatility in Applications

The other interesting aspect of an automatic grinding machine is that of flexibility. These machines can handle a lot of work with metals as well as plastics, ceramics, and composite materials. Also, they are applicable across different sectors; automotive, aerospace, and construction among others, making them an essential component for Indian manufacturers with contracts across different markets.

Advanced Control Systems

Present-day automatic grinding machines are fitted with complex control panels that simplify the use of the machines and increase efficiency. Such elements as touch screens, program control, and automatic feedback systems enable an operator to tweak grinding processes depending on conditions. Such advancements are especially helpful for the industries of India because the implementation of smart manufacturing technologies is possible.

Energy Efficiency

Fault tolerance however is an important factor in manufacturing today’s complicated machinery where energy efficiency is a big factor. Automatic grinding machines are designed with utmost consideration being made on the power consumption rates and the production rates. This is because their motor systems are well designed and their energy management is efficiently arranged ensuring low operational costs making them friendly in the environment and pocket-friendly for industries in India.

Beat and Toughest Structure

It works well as an industrial grinder, proving the reliability of the design and endurance of the machine. These machines use superior materials and engineering to be executed under harsh operating conditions, evenly providing long-term returns to manufacturers in India.

Reduced Labor Costs

Automatic grinding machines perform most of the grinding functions hence reducing the amount of time workers spend doing these jobs. This not only cuts down the operating expenses but also ensures that the efficient workers employ their time in doing challenging tasks that increase the efficiency levels. For industries in operation in India, where labor costs bear much of the cost of production, this makes it a key feature of Automatic Grinding Machines.

Safety Features

All employees in industries must be concerned a lot about their safety. The key feature of the Automatic grinding machine possess protective enclosures, emergency stop buttons, and automatic shut-down facilities in case of an eventuality. These features make the working environment safer for the operators and reduce the number of cases of accidents.

Environmental Benefits

Besides energy efficiency, the key features of automatic grinding machines include use and are developed with a special focus on reducing wastage. It also aims for a sustainable manner in the production process as its capability to delicately tune the grinding parameters minimizes material losses. This correlates with the current trends as a result of sustainability in production in India.

Ease of Maintenance

Last but not least, there is always little question that an important aspect of any surface grinding machine is how easy it is to maintain. The structure of machines is such that most of them are built with standard parts and have built-in self-checking capacities so that localization of problems is not necessarily a time-consuming process. This reduces downtime and increases the overall useful life of the equipment leading to optimization of the costs that accrue to Indian manufacturers.

Conclusion

The automatic grinding machine is an important piece of equipment in undergoing manufacturing processes with various benefits including accuracy, speed, flexibility, and being environment friendly. Hence for industries in India such an investment leads to an increase in productivity as well as the profitability of the business. This research proposal aims to identify and examine the key features of Automatic Grinding Machines to enable manufacturers to make appropriate choices in improving their ground operations and relevance in the current industrial marketplace.