32/34, Jintan Udhyognagar, Behind Gas godown, Surendranagar – 363 002, Gujarat, INDIA.

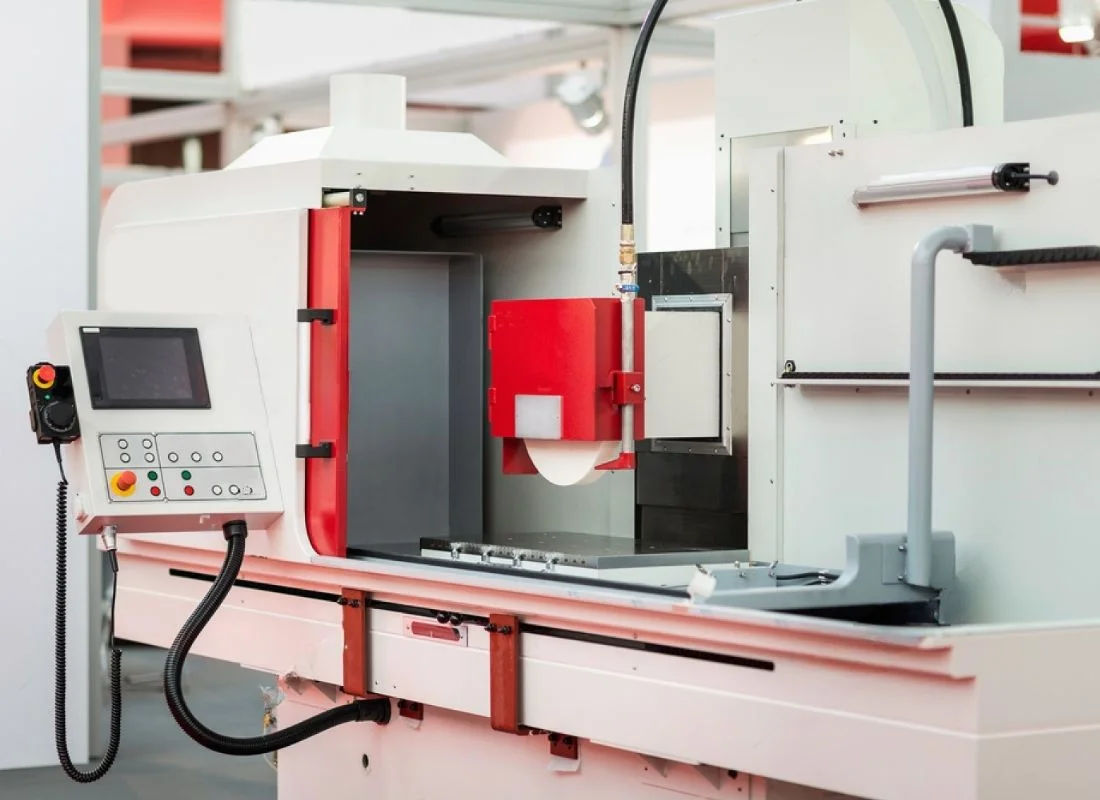

A Complete Overview of

Hydraulic Surface

Grinding Machine

Introduction:

There are different types of grinders on top. In a horizontal axis-mounted machine, all edges of the plate are in contact with the workpiece. This creates a smooth surface. This type of hydraulic surface grinding machine (circular grinding) usually involves a very precise job and is usually done on a flat surface.

Pinnacle of India provides hydraulic grinders that provide efficient and accurate surface grinding solutions. These machines use hydraulic dynamics to control the movement of the mill and workpiece, resulting in high efficiency and precision.

The hydraulic system allows quick and precise adjustment of the position of the sand platform, table movement, and vertical feed, allowing the operator to achieve the desired end and surface dimensions.

Main Purpose:

One sort of machine tool used to grind flat surfaces is a Hydraulic Surface Grinding Machine. The machine's movement and functioning are managed by hydraulic power, which enables accurate control and seamless application.

The SGC series hydraulic surface grinding machine is suitable for mortar and pestle, automotive, and heavy machinery industries and can be used for prestressing steel, iron, non-ferrous and non-ferrous metals, and other large and medium parts.

How it Works?

The processor is placed on the table.

The grinding plate moves down to the workpiece and begins rotating.

The hydraulic system controls the movement of the wheel head and table, allowing for precise control and efficiency.

The grinder removes material from the workpiece, thus achieving the desired surface finish.

Applications:

- Aerospace: construction of airplane components such as engine components and turbine blades.

- Automobiles: A hydraulic surface grinder can be used in the construction of engine blocks, cylinders, and engine components.

- Manufacturing: building tools and dies for various industries.

- General engineering: structure factors for machines, pumps, and gearboxes.

Advantages of Hydraulic Surface Grinding Machine

Our Extreme Series hydraulic surface grinders feature advanced technology and high performance, making them an ideal choice for artificial operations. Ameliorate your face grinding chops with the trust ability and perfection of our hydraulic surface grinder to insure optimal results in every operation.

A hydraulic face grinder has numerous advantages:

Precision: It can produce flat surfaces with high accuracy and precision.

Effective: able to quickly grind surfaces and remove material efficiently.

Versatility: They have the ability to melt a wide range of materials, such as composites, metals, and ceramics.

Smooth Surfaces: produces a smooth surface that enhances the part's look and performance.

Cost-effective: It is economical for the majority of diligence because it can be applied to both small- and large-scale items.

Durability: They are made with long-term durability and usability in mind.

Customization: May be formed and tailored to meet the needs of a particular client.

High toughness: They have a strong core structure and excellent toughness.

Direct drive: They have a direct drive feature that eliminates vibration.

Features of Hydraulic Surface Grinder

A hydraulic surface grinder is a powerful machine used for a variety of metal applications. There are many features, such as:

Accuracy: Hydraulic ground grinders provide high grinding accuracy.

Rigidity: Hydraulic surface grinders have a sturdy base and a slider with excellent rigidity.

Low noise: The vibration of the hydraulic surface grinding machine is stable with minimal noise.

It's simple to operate: Installing and getting used to hydraulic surface grinders is not difficult.

Cost-effective: When weighed against other grinders, hydraulic surface grinders are more economical.

Technical Characteristics

The hydraulic ground grinder has high rigidity, stable vibration, low noise, and low fuel temperature in the tank, very accurate grinding, and easy maintenance.

Exceptionally high-precision grinding heads and high-precision angle bearings. Fully sealed lubrication, long service life, and high accuracy.

3-axis guides, turcite coated, easy operation, and independent lubricants.

Program control series: Y and Z axes are controlled by an AC servo motor, and PLC system control synchronizes the automatic grinding cycle.

CNC series: Y and Z-axis feed adopts precision ball screw, AC servo motor with CNC setting control, high feed sensitivity, shape grinding, groove grinding, automatic progressive grinding, easy operation, and high efficiency.

Conclusion

The hydraulic surface grinder is equipped with high-quality factors and robust construction, icing life and trustability. They offer excellent strength, stiffness, and perfection, making them suitable for a wide range of artificial operations. With advanced features and easy-to-use controls, these hydraulic systems insure optimum performance and harmonious results.